CNC Prototyping

Quick Turn Machined Prototypes. Always On Time!

Share Machine, Inc. has a range of CNC machining options, including 3, 4, and 5-axis CNC metal-working processes. Our 5-axis CNC machine can produce complex three-dimensional shapes, such as turbines and impellers, rapidly and in a single set up. Our CNC lathe is great for heavy-duty cutting of large cylindrical parts. The live tooling option easily adds in slots, grooves and other complex features.

Our quick turn around prototyping process has the capacity to manufacture parts up to 20″ x 80″. With full 5-Axis machining capacity we can eliminate set-ups, save lead-time and reduce part cost. We specialize in close tolerance high precision tooling and parts done right and done fast.

We recommend CNC machining for metal prototypes

Share Machine’s rapid prototyping uses computer-aided design (CAD) and computer-aided manufacturing (CAM) technology to automatically construct models. Simply submit a drawing, sketch, or sample part and our machinists will produce a detailed CAD model from which the prototype will be constructed.

Prior to beginning the CNC machining process, machinists construct a prototype model, which serves as the customer and machinist’s final hands-on check for dimension, material, etc., before full-scale production is initiated. If requested, these models are tested to make certain that the best material has been chosen and the right CNC machining operation has been implemented.

CNC prototypes are ideal when the part is subjected to demanding functional tests, or the physical size of the parts make other prototyping methods cost prohibitive.

Advantages of Prototyping

Share Machine’s prototyping process can quickly manufacture parts at an affordable price

Rapid Prototyping With GibbsCAM

CAD/CAM Technology

Once the model is constructed, 3D CAD files are converted into a specific working format, which represents a three-dimensional surface as an assembly of pieces. Every file contains the precise coordinates of the vertices and the direction of each piece. Machinists at Share Machine balance accuracy and manageability to fabricate a useful working file.

Fit and function testing of prototypes avoids potential errors. At an early stage in production we are able to determine if a part is not machined to the right tolerances or if another material should be used. Testing verifies that we have obtained optimal prototypes prior to committing to erroneous tooling. With the right prototype as a guide, full-scale production runs smoothly and efficiently. Fast cycle times mean less labor, resulting in a better price to customers.

CNC prototypes are ideal when the part is subjected to demanding functional tests, or the physical size of the parts make other prototyping methods cost prohibitive.

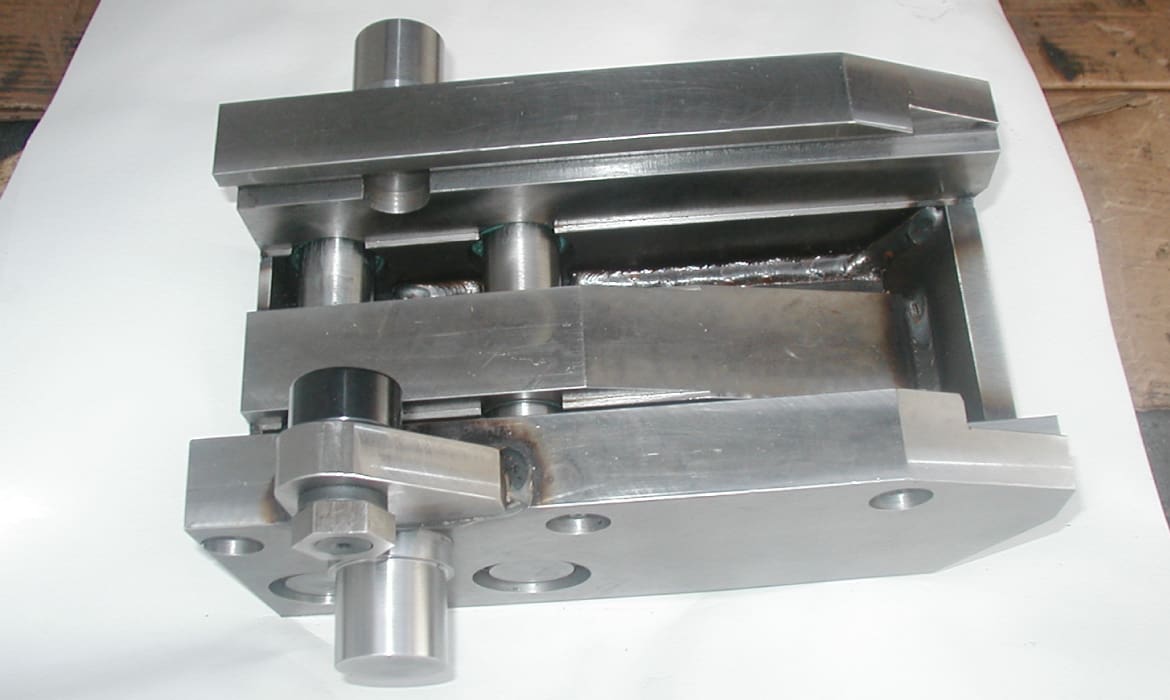

A Few Examples Of Our Prototyping Capabilities